Bolt Carrier Groups

The bolt carrier group is the heart of any AR10/AR15/M4/M16 type rifle, carbine or AR pistol. Bet-your-life dependability is a non-negotiable prerequisite. We carry Aero Precision, Toolcraft, Fail Zero and Spike's Tactical BCGs with Nickel Boron, Black Nitride, Ionbond DLC, Chrome/Magnesium Phosphate and Titanium Nitride-Gold finishes with M16 profile carriers. Chances are we have the AR BCG that you are looking for. See our Bolt Carrier Group Buyer's Guide.

-

On SaleBest Seller!See Best Price In Cart!

Toolcraft DLC C158 BCG 556

Toolcraft

Now: $159.99Was: $209.99Free Shipping on all Toolcraft Bolt Carrier Groups! Shop other BCG colors: Toolcraft FDE BCG, and Toolcraft Gray BCG. The Ionbond Diamond Like Carbon (DLC) finish is an incredibly hard (90 Rockwell) self-lubricating finish. This...Now: $159.99Was: $209.99 -

Best Seller!See Best Price In Cart!

Toolcraft Black Nitride BCG 556

Toolcraft

$99.99Free Shipping on all Toolcraft Bolt Carrier Groups! Toolcraft Inc. is an OEM manufacturer of bolt carrier groups (BCGs) for many AR15 makers. These companies know they can trust Toolcraft quality and are proud to have their logos applied to...$99.99 -

Out of StockOn SaleSee Best Price In Cart!

Toolcraft Phosphate C158 HPT BCG 556

Toolcraft

Now: $149.99Was: $179.99Free Shipping on all Toolcraft Bolt Carrier Groups! Toolcraft makes some of the best AR15 bolt carrier groups on the market today. Precision manufactured on state-of-the-art CNC machinery in North Carolina, Toolcraft products are trusted by the U.S...Now: $149.99Was: $179.99 -

On SaleSee Best Price In Cart!

Toolcraft Polished Titanium Nitride TiN C158 BCG 556

Toolcraft

Now: $189.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups. Titanium Nitride (TiN) is an extremely hard ceramic material, often used in aerospace and military applications that improves maintenance, cleaning, and edge retention. This finish provides a...Now: $189.99Was: $199.99 -

Out of StockOn SaleSee Best Price In Cart!

Toolcraft Polished DLC C158 BCG 556

Toolcraft

Now: $189.99Was: $209.99Free Shipping on all Toolcraft Bolt Carrier Groups! Shop other BCG colors: Toolcraft FDE BCG, and Toolcraft Gray BCG. The Ionbond Diamond Like Carbon (DLC) finish is an incredibly hard (90 Rockwell) self-lubricating finish. This makes...Now: $189.99Was: $209.99 -

Out of StockOn SaleSee Best Price In Cart!

Toolcraft DLC 9310 BCG 556

Toolcraft

Now: $139.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups! The Ionbond Diamond Like Carbon (DLC) finish is an incredibly hard (90 Rockwell) self-lubricating finish. This makes it extremely resistant to wear and corrosion. This also makes it an...Now: $139.99Was: $199.99 -

Out of StockSee Best Price In Cart!

Toolcraft 6.5 Creedmoor Double Ejector BCG DLC

Toolcraft

$269.99Free Shipping on all Toolcraft Bolt Carrier Groups! This Toolcraft 6.5 Creedmoor Bolt Carrier Group has been upgraded with a Diamond-Like-Carbon finish to make it the best 6.5 Creedmoor BCG available! Toolcraft engineers designed this bolt carrier group...$269.99 -

Out of StockOn SaleSee Best Price In Cart!

Toolcraft FDE DLC C158 BCG 556

Toolcraft

Now: $159.99Was: $229.99Free Shipping on all Toolcraft Bolt Carrier Groups! Shop other DLC BCG colors: Toolcraft DLC Black BCG and Toolcraft DLC Gray BCG. The Ionbond DLC finish is a metal based hard coating that provides a high level of scratch and...Now: $159.99Was: $229.99 -

On SaleSee Best Price In Cart!

Toolcraft Gray DLC C158 BCG 556

Toolcraft

Now: $129.99Was: $209.99Free Shipping on all Toolcraft Bolt Carrier Groups! Shop other BCG colors: Toolcraft DLC Black BCG, and Toolcraft DLC FDE BCG. The Ionbond DLC finish is a metal based hard coating that provides a high level of scratch and wear...Now: $129.99Was: $209.99 -

Out of StockOn SaleOn Order!See Best Price In Cart!

Toolcraft Polished Chrome BCG 556

Toolcraft

Now: $189.99Was: $224.99Free Shipping on all Toolcraft Bolt Carrier Groups! See also our Matte Chrome BCG. We are extremely pleased to finally be able to offer a chrome bolt carrier group manufactured by Toolcraft! These BCGs exceeded our expectations. The combination...Now: $189.99Was: $224.99 -

On Sale

Aero Precision Black Nitride BCG No Logo "Stealth" 556

Aero Precision Products

Now: $166.65Was: $170.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR15 parts manufacturing and this Bolt Carrier Group is...Now: $166.65Was: $170.00 -

On SaleSee Best Price In Cart!

Toolcraft Phosphate C158 BCG 556

Toolcraft

Now: $129.99Was: $169.99Free Shipping on all Toolcraft Bolt Carrier Groups! Toolcraft makes some of the best AR15 bolt carrier groups on the market today. Precision manufactured on state-of-the-art CNC machinery in North Carolina, Toolcraft products are trusted by the U.S...Now: $129.99Was: $169.99 -

On SaleBest Seller!

Aero Precision Black Nitride BCG 556

Aero Precision Products

Now: $166.65Was: $170.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR15 parts manufacturing and this Bolt Carrier Group is...Now: $166.65Was: $170.00 -

Out of StockBest Seller!See Best Price In Cart!

Toolcraft Nickel Boron BCG 556

Toolcraft

$129.99 - $159.99Free Shipping on all Toolcraft Bolt Carrier Groups! A Toolcraft Nickel Boron BCG is, hands down, one of the best Nickel Boron BCGs (NiB BCG) on the market today. The bolt carrier group is one of the most important AR15 parts, critical to the safety and...$129.99 - $159.99 -

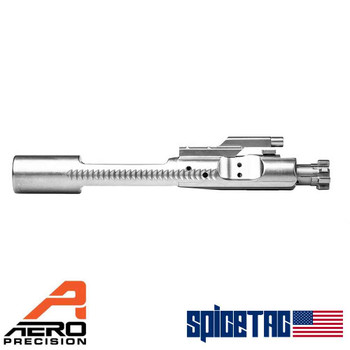

Aero Precision Nickel Boron BCG 556

Aero Precision Products

$210.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR15 parts manufacturing and this Nickel Boron...$210.00 -

Aero Precision Nickel Boron BCG No Logo "Stealth" 556

Aero Precision Products

$210.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR15 parts manufacturing and this Nickel Boron Bolt...$210.00 -

On SaleSee Best Price In Cart!

Toolcraft FDE DLC BCG 308 - BLEM

Toolcraft

Now: $199.99Was: $299.99Free Shipping on all Toolcraft Bolt Carrier Groups! This BLEM item may contain minor scuffs, dings and rub marks from shipping. They are mechanically 100% and are covered by the Toolcraft Lifetime Warranty. This Toolcraft 308 FDE DLC Bolt Carrier Group...Now: $199.99Was: $299.99 -

On SaleSee Best Price In Cart!

Toolcraft DLC BCG 7.62X39

Toolcraft

Now: $139.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups! Note: This 7.62X39 BCG is not compatible with the Palmetto State Armory KS-47 Your 7.62X39 build deserves the best bolt carrier group! This 7.62X39 BCG by Toolcraft is the highest quality BCG on...Now: $139.99Was: $199.99 -

Out of StockOn SaleSee Best Price In Cart!

Toolcraft DLC BCG 6.5 Grendel

Toolcraft

Now: $169.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups! Your 6.5 Grendel build deserves the best bolt carrier group! This 6.5 Grendel BCG by Toolcraft is the highest quality BCG on the market today. The Ionbond Diamond Like Carbon (DLC) finish is an...Now: $169.99Was: $199.99 -

On SaleSee Best Price In Cart!

Toolcraft Nickel Boron BCG 7.62x39

Toolcraft

Now: $149.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups! Note: This 7.62X39 BCG is not compatible with the Palmetto State Armory KS-47 Your 7.62x39 AR build deserves the best bolt carrier group money can buy. This 7.62x39 Nickel Boron BCG by Toolcraft...Now: $149.99Was: $199.99 -

On SaleSee Best Price In Cart!

Toolcraft Nickel Boron BCG 6.5 Grendel

Toolcraft

Now: $149.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups! Your 6.5 Grendel build deserves the best bolt carrier group money can buy. This 6.5 Grendel Nickel Boron Type 2 BCG by Toolcraft is the highest quality BCG on the market today. Finished in Nickel Boron...Now: $149.99Was: $199.99 -

On SaleSee Best Price In Cart!

Toolcraft Black Nitride BCG 6.5 Grendel

Toolcraft

Now: $109.99Was: $159.99Free Shipping on all Toolcraft Bolt Carrier Groups! Your 6.5 Grendel build deserves the best bolt carrier group money can buy. This 6.5 Grendel Type 2 BCG by Toolcraft is the highest quality BCG on the market today. Finished in Black Nitride for a...Now: $109.99Was: $159.99 -

Out of Stock

Radian Weapons Enhanced Bolt Carrier Group 556

Radian Weapons

$219.99Free Shipping on Radian Weapons BCGs! The Enhanced Bolt Carrier Group for AR15/M16 platform weapons was designed to minimize carrier tilt and reduce friction inside the upper receiver by relocating key bearing surfaces. All materials, tolerances, and...$219.99 -

On Sale

Aero Precision Phosphate BCG 556

Aero Precision Products

Now: $166.65Was: $170.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR15 parts manufacturing and this Bolt Carrier Group is...Now: $166.65Was: $170.00 -

On Sale

Aero Precision Phosphate BCG No Logo "Stealth" 556

Aero Precision Products

Now: $166.65Was: $170.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR15 parts manufacturing and this Bolt Carrier Group is...Now: $166.65Was: $170.00 -

On SaleSee Best Price In Cart!

Toolcraft Nickel Boron BCG 458 SOCOM

Toolcraft

Now: $109.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups! Your 458 SOCOM build deserves the best bolt carrier group money can buy. This 458 SOCOM Nickel Boron BCG by Toolcraft is the highest quality BCG on the market today. Nickel Boron is an extremely...Now: $109.99Was: $199.99 -

On SaleSee Best Price In Cart!

Toolcraft Nickel Boron BCG 450 Bushmaster

Toolcraft

MSRP: $199.99Now: $109.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups! Your 450 Bushmaster build deserves the best bolt carrier group money can buy. This 450 Bushmaster Nickel Boron BCG by Toolcraft is the highest quality BCG on the market today. Nickel Boron is an...MSRP: $199.99Now: $109.99Was: $199.99 -

Out of Stock

Fail Zero Nickel Boron BCG 556

FailZero

$169.99Free Shipping on all Fail Zero Bolt Carrier Groups! FailZero is the undisputed pioneer of Nickel Boron technology. When failure is not an option, you can depend on Fail Zero. This Fail Zero BCG is fully assembled and drop-in ready for most Mil-Spec...$169.99 -

Out of Stock

Aero Precision PRO Series Black Nitride BCG 556

Aero Precision Products

$195.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. The Aero Precision PRO 5.56 Bolt Carrier Group is built from the ground up to meet the...$195.00 -

On SaleSee Best Price In Cart!

Toolcraft Titanium Nitride TiN C158 BCG 556

Toolcraft

Now: $139.99Was: $199.99Free Shipping on all Toolcraft Bolt Carrier Groups. Titanium Nitride (TiN) is an extremely hard ceramic material, often used in aerospace and military applications that improves maintenance, cleaning, and edge retention. This finish provides a...Now: $139.99Was: $199.99 -

Out of Stock

Spike's Tactical M16 BCG 556

Spikes Tactical

$149.99Free Shipping on all Spike's Tactical BCGs! This is the same BCG Spike’s uses on their builds. These complete bolt carrier groups come magnetic particle inspected and high pressure tested. The carrier is made from 8620 steel and the bolt from 158...$149.99 -

Out of StockOn SaleSee Best Price In Cart!

Toolcraft Nickel Boron (C158) BCG Left Hand 556

Toolcraft

Now: $199.99Was: $224.99Toolcraft Left Handed Bolt Carrier Groups Ship FREE. Your Left-Handed AR15 Build deserves the best quality BCG you can get - Toolcraft! This quality Toolcraft bolt carrier group has all the outstanding specs of the right-handed Toolcraft BCG, but it's...Now: $199.99Was: $224.99 -

Out of StockOn Sale

Toolcraft Phosphate BCG 556

Toolcraft

Now: $109.99Was: $149.99Free Shipping on all Toolcraft Bolt Carrier Groups! Toolcraft makes some of the best AR15 bolt carrier groups on the market today. Precision manufactured on state-of-the-art CNC machinery in North Carolina, Toolcraft products are trusted by the U.S...Now: $109.99Was: $149.99 -

Out of Stock

Toolcraft Titanium Nitride TiN BCG 556

Toolcraft

$199.99Free Shipping on all Toolcraft Bolt Carrier Groups. Titanium Nitride (TiN) is an extremely hard ceramic material, often used in aerospace and military applications that improves maintenance, cleaning, and edge retention. This finish provides a...$199.99 -

Out of StockNew Product!

Toolcraft FDE DLC BCG 556

Toolcraft

$169.99Free Shipping on all Toolcraft Bolt Carrier Groups! The Ionbond DLC finish is a very hard self-lubricating finish. This makes it extremely resistant to wear and corrosion. This also makes it an ideal finish for a critical part like an AR15...$169.99 -

Aero Precision Black Nitride BCG 6.5 Grendel

Aero Precision Products

$175.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR15 parts manufacturing and this Bolt Carrier Group is...$175.00 -

Out of Stock

Aero Precision Black Nitride BCG 308

Aero Precision Products

$260.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR parts manufacturing and this Bolt Carrier Group is...$260.00 -

Out of Stock

Aero Precision Nickel Boron BCG 308

Aero Precision Products

$270.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR parts manufacturing and this upgraded Nickel Boron...$270.00 -

Out of Stock

Aero Precision Phosphate BCG 308

Aero Precision Products

$245.00Free Shipping on all Aero Precision BCGs! Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision. Aero Precision is a leader in AR parts manufacturing and this Phosphate finished Bolt...$245.00 -

Out of Stock

Toolcraft Titanium Nitride BCG 6.5 Grendel

Toolcraft

$199.99Free Shipping on all Toolcraft Bolt Carrier Groups. Titanium Nitride (TiN) is an extremely hard ceramic material, often used in aerospace and military applications that improves maintenance, cleaning, and edge retention. This finish provides a...$199.99