Aero Precision Products

Aero Precision PRO Series Black Nitride BCG 556

- SKU:

- APRH101767C

- Maximum Purchase:

- 15 units

Description

Free Shipping on all Aero Precision BCGs!

Should you need an Aero Precision product we don't carry, we recommend going directly to the great folks at Aero Precision.

The Aero Precision PRO 5.56 Bolt Carrier Group is built from the ground up to meet the demands of the most extreme conditions. Each component and manufacturing process of the PRO 5.56 Bolt Carrier Group was deliberately chosen to increase the reliable service life of the bolt carrier group and its components.

Bolt

The bolt is one of the most important parts of the bolt carrier group. Machined from 9310 steel, a proprietary flash nitride process was chosen to ensure proper heat treatment on the bolt. When properly heat treated, 9310 steel provides superior strength and durability when compared to C158.

The cam pin channel is counter bored, eliminating the need for swaging. Swaging is the industry standard, however this process creates more stress on the bolt during manufacturing by displacing material rather than cutting it to the proper dimension from the start.

- Machined from 9310 steel

- Shot peened

- MPI tested

- Proper heat treatment ensured via proprietary flash-nitriding process

Cam Pin

Each PRO cam pin is precision ground after heat treatment to exacting specifications and given a nitride finish.

The cam pin features an engraved indexing mark on one side of the cam pin face; a concept that has been popularized by Chad Albrecht at School of the American Rifle. Cam pins traditionally wear more heavily on one side and when installed inconsistently can create excessive wear over time. When the cam pin becomes “loose” this can create excessive wear on the bolt itself shortening overall life. The indexing mark allows for consistent installation during maintenance which in turn reduces wear on not only the cam pin but the bolt over time to help extend overall service life.

- Machined from 4140 steel

- Precision ground after heat treatment

- Engraved indexing mark

- Nitride finish

Extractor

The extractor features a phosphate finish. The extractor is one of the few places where it is beneficial to have a “rougher” finish as it allows for more positive engagement with the case when pulling it out of the chamber.

- Machined from 4140 steel

- Heat treated

- Shot peened

- Phosphate finish

Carrier

Each PRO BCG utilized an M16 cut carrier and features a nitride finish. Internal critical surfaces are precision ground to exacting tolerances to ensure optimal gas efficiency. The same machining standards are used for the carrier rails providing a super smooth fit and function from the start.

- Machined from 8620 steel

- M16 Cut Carrier

- Nitride Finish

- Critical surfaces precision ground for optimal gas efficiency and reliability

Gas Key

- Machined from hardened 4140 steel

- Torqued to spec with grade 8 hex fasteners

- Properly staked to mil-spec

- Nitride finish

Ejector

- Machined from S7 tool steel

Firing Pin

- Ground from 8640 steel

- Nitride Finish

This is a 223/5.56/300 Blackout bolt carrier group.

This AR BCG will not work with 6.5/6.8/308 etc.

| Bolt | Shot Peened; MPI |

| Bolt Material | 9310 Steel |

| Bolt Finish | Black Nitride |

| Caliber | 223/5.56/300 Blackout |

| Extractor O-ring | Viton; Mil Spec |

| Carrier Material | 8620 Steel |

| Carrier Finish | Black Nitride |

| Carrier Design | M16 Full Auto Style, Properly Staked |

About Aero Precision

Manufacturing

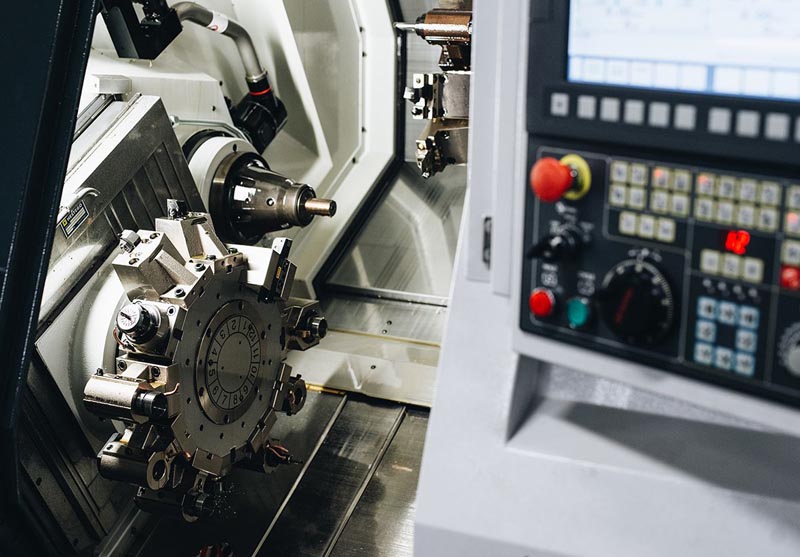

At Aero Precision we're known for two things: superior engineering & machining, and the ability to get the customer what they need, when they need it. Our products have been recognized across the country by members of the military and law enforcement communities for a simple fact - they work better.

Our goal is simple: technical perfection

Aero Precision’s roots are deeply tied to aerospace, and our drive for clean, perfect engineering and machining stems from that. When you’re building something that will fly in the air, there is no margin for error. We take that same approach in the firearms industry. Not every manufacturer will have razor thin tolerance levels. Not every manufacturer will personally oversee the development, design and machining of every part that comes off the line. We’re not every manufacturer.

State of the art in every way

Manufacturing a great receiver isn’t just about what the end product looks like. It’s about what it feels like, how it works, how it handles and performs. To ensure that each and every one of these elements meets the mil-spec standard, we look at the process from which the product was created at a holistic level. We push the boundaries of manufacturing and challenge the status quo by constantly looking for new ways to use, develop or evolve existing processes. By personally designing and engineering state of the science tooling in-shop, we’re able to leverage the latest machine tool technologies to provide you with components of the highest quality.

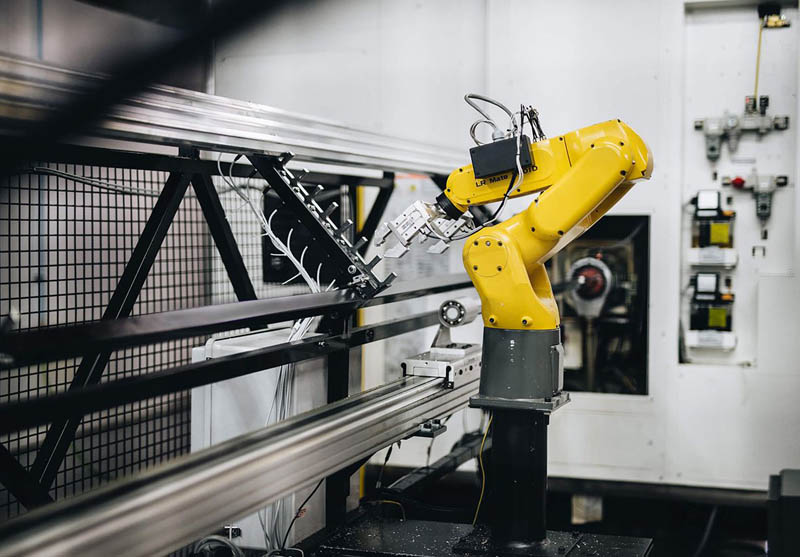

Our investment, your benefit

Rail guided robotic equipment, new horizontal machining centers with sophisticated monitor devices and hydraulic tooling to ensure consistent loading. These pieces of equipment are standard in our shop and exemplify the dedication we have to investing in our work. We engineer total process control. We have made and continue to make the upfront investment to produce the highest quality components day after day. Are there cheaper ways to build the same product? Sure. Would you as the end user see a difference in the way it works? You better believe it. Better engineering builds better components. It’s just that simple.

OEM Provider - A reputation you can count on

We don’t settle for anything less than perfection. And we don’t say that lightly. As a key manufacturer for many OEM suppliers, we know that it’s not just about the quality of the part we provide, it’s our ability to get the right product out the door at the right time. We’re committed to providing our OEM customers with the exacting attention to detail you’ve come to expect from Aero Precision. We don’t expect anything less. Neither should you. Being an OEM supplier means that we’re putting more than just our reputation on the line, we’re putting yours out there as well. We understand that risk and know what it takes to build a high-quality relationship in addition to a high-quality product. By working closely with you we build a partnership throughout the entirety of the project from design to engineering and final execution. This partnership based on trust, integrity and competence is what gives our customers the end results they want and need.