Best AR15 BCG Finishes - Pros Cons and Recommendations

Above: AR15 BCG finishes (l-r) Toolcraft Titanium Nitride, BCM BCG with Robar NP3+, Toolcraft Nickel Boron, Toolcraft Black Nitride, Colt BCG refinished in Chrome with Nickel Boron Gas Key, Toolcraft Diamond Like Carbon (DLC) Finish, Toolcraft Chrome Phosphate

There's a vast number of finishes available for AR-15 bolt carrier groups (BCGs) today. I don't mind paying more for more performance, but I don't like to waste my money on gimmicks either.

Let's sort through some of the more popular BCG finishes and coatings and see the Pros, Cons and Recommendations!

Skip to a section:

Hard Chrome

Above: Colt BCG refinished with matte chrome finish and nickel boron gas key

The very first AR15 bolt carrier groups were hard chrome plated. This was at the direction of Eugene Stoner, the designer of the AR-15.

Chrome is a finish well suited to the harsh environment where the bolt carrier group operates. Chrome is extremely hard which makes it very wear resistant. It also has high corrosion resistance as well as a natural lubricity.

Today, other finishes are much more common, all of which try to improve on the original chrome in either price or performance. In fact, chrome BCGs are somewhat difficult to find today, but worth it if you can find one.

Pros

Durable and corrosion resistant

Easy clean-up

Cons

More expensive than some other finishes

Recommendations

Brownells Chrome Bolt Carrier Group

Brownells products are quality through and through. This beautiful chrome BCG is no exception. Built for a lifetime of hard use, this BCG can take all the punishment you can throw at it.

Phosphate

Above: Toolcraft BCG with Manganese Phosphate finish

Current mil spec for bolt carrier groups in military rifles (M16 and M4) is phosphate. Some advantages of phosphate over chrome include it’s lower cost and less visible appearance in a military setting - less shiny.

Properly manufactured BCGs with a phosphate finish will still have a chrome lining inside the gas key and inside the carrier where the gas rings ride. None of the other finishes (Nitride, DLC, Titanium Nitride, etc) will be chrome lined in these areas.

Above: Chrome lining inside Toolcraft phosphate carrier can be seen with light coming in from the cam pin slot

Some people like the rough phosphate finish for it’s tendency to “hold oil” better than other finishes. The roughness of the phosphate finish wears down to become a smooth surface on the high wear points like the carrier rails.

Pros

Very economical

Durable and corrosion resistant

Mil-Spec

Cons

Rough finish that requires more lubricant to run smoothly

Cleaning is more difficult

Recommendations

Bravo Company (BCM) Bolt Carrier Group (Brownells)

BCM has earned an excellent reputation and their BCGs are top of the line.

Colt Bolt Carrier Group (Brownells)

Colt needs no introduction. The original, mil-spec BCG!

Toolcraft Phosphate Bolt Carrier Group (SpiceTac)

Toolcraft is an OEM provider of BCGs to many firearms manufacturers. See our review here: Toolcraft Chrome Phosphate BCG Review

Black Nitride

Above: Toolcraft BCG with Black Nitride finish

Also known as Melonite, Salt Bath Nitride or simply Nitride, this is a heat treating process that creates a case hardened surface by diffusing nitrogen into the metal surface. The resulting surface is extremely hard which makes it very resistant to wear and corrosion. It is also smooth and slick which makes for smooth operation and easier cleaning.

Because nitrided bolt carrier groups do not require chrome lining of the gas key or inner areas of the bolt carrier, manufacturing costs are reduced. Black Nitride finished BCGs often have an attractive deep black finish.

Pros

High durability and corrosion resistance

Smooth finish requires less lube

Easier to clean than phosphate

Cons

Can cost more than phosphate

Comparisons

Black Nitride vs Phosphate

These are two of the least expensive finishes available. Nitride has the edge when it comes to smoothness and hardness. It also requires less lubricant to work well and is easier to clean. Nitride has many advantages but it is not mil-spec for BCGs and that is an important consideration for some.

Phosphate has been serving the military well for many years and it works very well. For the traditionalist, a phosphate BCG has a texture that just feels right. Either will get the job done. On the basis of performance, nitride wins. For nostalgia, phosphate wins.

Black Nitride vs Chrome

These two super hard finishes are both easy to clean workhorses that will take the punishment and come back for more. A chrome BCG will be significantly more difficult to find and more expensive when you do find one. If you go chrome it will probably be for the color and the uniqueness of the finish. Or you are doing a retro build, which I can appreciate! Chrome is a timeless classic and you really don't need a reason to choose it. But if you want all the functionality at half the price? Yea, nitride is just fine!

Recommendations

Aero Precision Black Nitride BCG (SpiceTac)

Aero Precision BCGs are top of the line.

Toolcraft Black Nitride BCG (SpiceTac)

Toolcraft is an OEM provider of BCGs to AR15 manufacturers. See our review here: Toolcraft BCG Review - Best Black Rifle Secret Ever?

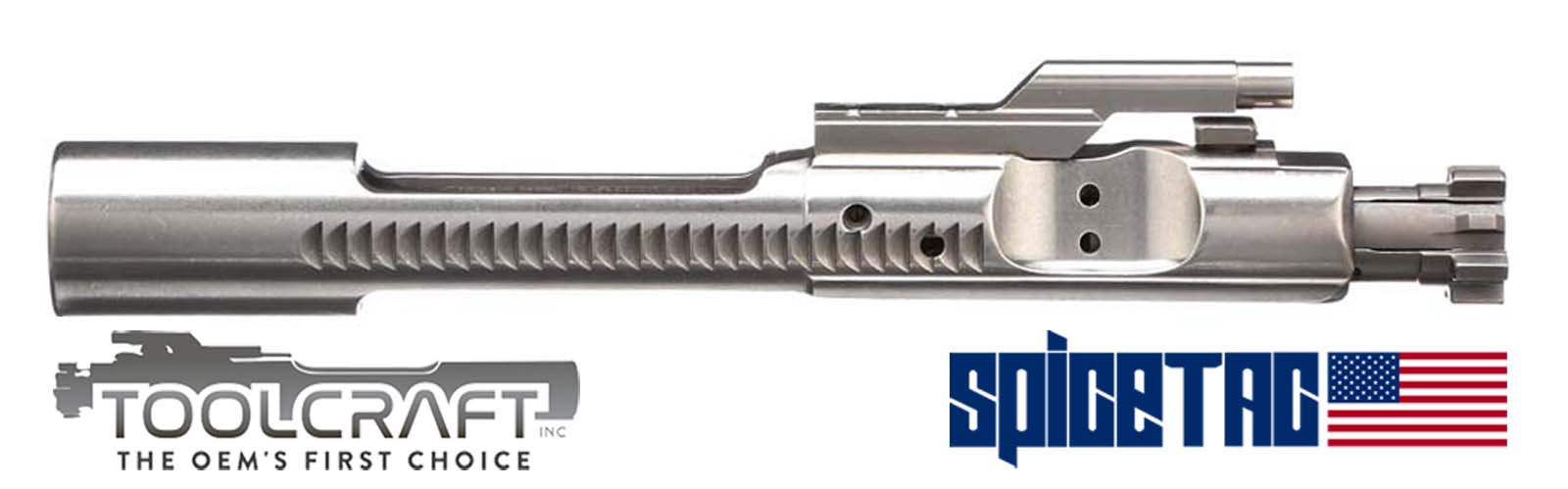

Nickel Boron

Above: AR-15 BCGs with Nickel Boron finish by Fail Zero (Top) and Toolcraft (Bottom)

Nickel Boron is an advanced metal finish that offers high resistance to wear and corrosion as well as having an ultra low co-efficient of friction. A nickel boron bolt carrier group will have greater lubricity and corrosion resistance than both chrome and nitride BCGs. For these reasons, it is a very popular AR-15 BCG finish.

UCT Coatings of Palm City Florida applies their patented EXO Nickel Boron finish to many products including AR-15 BCGs for Fail Zero and Toolcraft. That Nickel Boron finish is MIL-SPEC on some Army mortar tube components.

Pros

Slickness

Durability

Corrosion resistance

Cons

Can cost more than some other finishes

Comparisons

Nickel Boron vs Nitride

Both of these finishes are far ahead of phosphate as far as slickness and ease of clean up are concerned. In both categories though, Nickel Boron has the edge over Nitride. Nickel Boron usually costs more than Nitride and that money goes to more performance. Is that little bit of extra performance important to you? If it is and you want to spend the money and you like the color, well then it just might be a Nickel Boron kind of a day for you! If none of that is you then Black Nitride and done!

Nickel Boron vs Chrome

This is the battle of the silver finishes. Old school vs new school. Hard Chrome has the edge in hardness but Nickel Boron wins on slickness. Both are superior finishes with distinctly different looks. Nickel Boron tends to have more shine especially compared to matte chrome. Nickel Boron is easy to find today while Chrome is hard to find and generally more expensive. They are both winners, go with the finish that gives you the finished look you want.

Recommendations

Aero Precision Nickel Boron BCG (SpiceTac)

Aero Precision products are solid and their bolt carrier groups are no exception.

Fail Zero Nickel Boron BCG (SpiceTac)

Fail Zero BCGs use the patented EXO Nickel Boron finish.

Toolcraft Nickel Boron BCG (SpiceTac)

For a more detailed look at Nickel Boron see our blog post: Top 3 Reasons You Might Want a Nickel Boron BCG

Also see our review of the Toolcraft Nickel Boron BCG here: Toolcraft Nickel Boron BCG Review and our review of the Fail Zero BCG here: Fail Zero BCG Review.

Diamond Like Carbon (DLC)

Above: Toolcraft BCG with Diamond DLC finish

Ionbond Diamond Like Carbon (DLC) Coating is a state-of-the-art metal finish applied through a Physical Vapor Deposition (PVD) process. It is an extremely tough, corrosion proof coating, with excellent low-friction properties.

Ionbond Black DLC will not chip, crack or peel, providing you with years of reliable function and protection against wear. It is so strong that it is virtually scratch proof. It has an attractive gray graphite-like appearance.

Above: Toolcraft Black DLC BCG installed with black anodized Aero Precision upper, lower and M-LOK handguards.

It's a difficult finish to apply and as a result it is one of the more expensive finishes. It is available in a variety of colors including Black, Gray and FDE. See our Toolcraft DLC BCG review here: Toolcraft Diamond DLC BCG - The Best BCG Ever Made?

Pros

Extreme hardness and corrosion protection

Smooth with low coefficient of friction

Cons

Expensive

Recommendations

Above: Toolcraft BCG with Titanium Nitride finish

Titanium Nitride is an extremely hard ceramic material, often used in aerospace and military applications that improves the maintenance, cleaning, and edge retention.

This finish has excellent lubricity, hardness, and corrosion resistance, but those benefits can be found in other finishes. The main reason to get this finish is going to be appearance. The gold color is unique and makes a very nice contrast against the matte black of the AR15.

Pros

Smooth, hard, slick, corrosion resistant

Gold plated looks

Cons

Price

Recommendations

Toolcraft Titanium Nitride BCG (SpiceTac)

Robar NP3+

Above: This Bravo Company (BCM) BCG has been refinished with NP3+ by Robar

NP3 is a proprietary finish offered by Robar Inc. It is an electroless nickel-based finish for steel, stainless steel and aluminum alloys that co-deposits sub-micron particles of PTFE (polytetrafluoroethylene), otherwise known as Teflon™, with electroless nickel. It is extremely slick while also being very corrosion resistant. It has a dull gray finish darker than chrome and nickel boron.

The finish is valued for its slickness and durability. Firearms instructor John Farnam has NP3 applied to not only the BCG but also the inside of the upper and lower receivers of his custom FSM4 AR15s.

It can be difficult to find BCGs finished in NP3 and it usually requires sending yours in to Robar to be plated.

Pros

Slick, durable

Cons

Expensive especially since you will probably have to send yours in to be refinished

Conclusion and Final Recommendations

When it comes to finishes for AR-15 BCGs, the sky is the limit. All of the finishes listed here are quality finishes and a good BCG will work fine with any of them. What finish you select becomes pretty much a matter of personal preference.

My preferences? If I want a black finish and I have the money, DLC all day long. Black Nitride is a very good second choice for less money. Phosphate would be my last choice but if I am feeling nostalgic then it's the only choice.

If I want to add a little color or bling to a rifle then I remember the song "Silver and Gold" from the Rudolph The Red Nosed Reindeer movie. At that point it's a Nickel Boron (Silver) vs Titanium Nitride (Gold) discussion and that's a discussion for another day!

For specific comparisons of black finishes (Phosphate vs Nitride vs DLC ) see here The Best Black BCG Finish - Phosphate vs Nitride vs DLC

For views of different finishes see our Toolcraft Gallery.

See our BCG recommendations: Best AR15 Bolt Carrier Groups

When that build is complete be sure to shop for ammo here: Buy Ammo Online.

Thank you for visiting.

Recent Posts

-

10 Best Places To Buy Ammo Online [2025]

If you like convenience, selection and low prices, online ammo shopping is for you! Please see …Jan 02, 2025 -

Best Handguns: Beginners & Home Defense [2025]

What's the best handgun for a beginner? How about the best home defense pistol? It's best to ar …Jan 01, 2025 -

Best 380 Ammo for Self Defense & Target Shooting [2025]

380 ACP (Automatic Colt Pistol), also known as 9x17mm, 9mm Browning, 9mm short... and the list …Dec 20, 2024

![10 Best Places To Buy Ammo Online [2025] 10 Best Places To Buy Ammo Online [2025]](https://cdn11.bigcommerce.com/s-3oo7xhnyq8/images/stencil/160w/uploaded_images/where-to-buy-bulk-cheap-ammo-online.jpg)

![Best Handguns: Beginners & Home Defense [2025] Best Handguns: Beginners & Home Defense [2025]](https://cdn11.bigcommerce.com/s-3oo7xhnyq8/images/stencil/160w/uploaded_images/glock-17-w-weapon-light.jpg)

![Best 380 Ammo for Self Defense & Target Shooting [2025] Best 380 Ammo for Self Defense & Target Shooting [2025]](https://cdn11.bigcommerce.com/s-3oo7xhnyq8/images/stencil/160w/uploaded_images/walther-380-acp-pistol-banner.jpg)